Small Collision, Big Cost: How Column Protectors Prevent Warehouse Disasters

[rank_math_breadcrumb]

In warehouses and storage facilities, often the small incidents carry the biggest price tags. A minor collision between a forklift and a structural column may not look catastrophic at first glance, however, the reality is very different. The cost of repairing structural damage, downtime, and the potential risks to worker safety can quickly escalate.

Column protectors may seem like a simple piece of safety equipment, but their role in preventing workplace disasters cannot be overstated.

Warehouses and storage facilities are dynamic environments. With forklifts, pallet jacks, order pickers, and other vehicles constantly moving, the risk of accidental impacts is ever-present. Columns positioned in high-traffic zones are vulnerable to collisions, particularly where visibility is reduced, corners are tight, or workflow pressures increase the likelihood of human error.

Even a “small” impact can compromise the structural integrity of a building. Damaged columns may not fail immediately, but they can weaken over time, creating long-term hazards that put workers, equipment and the facility itself at risk.

When a warehouse column is impacted, it often isn’t as simple as repairing or replacing the damaged steel or concrete. In many cases, businesses are legally required to bring in a structural engineer to assess the damage and certify the column as safe. This process not only adds significant expense, but can also cause long delays while inspections, reports, and re-certifications are carried out.

Engineering assessments can run into thousands of dollars, and if the damage is extensive, the costs quickly escalate. On top of the fees, businesses may need to shut down or restrict operations in the affected area until clearance is given, compounding the financial impact through lost productivity.

What might appear as a “small dent” can end up triggering a chain of compliance obligations and unexpected costs that far outweigh the investment in preventative protection like column guards.

Fixing structural damage is costly. A small impact today can mean extensive repairs tomorrow.

Damaged columns can force part of the warehouse to shut down for safety reasons, disrupting operations and productivity.

A weakened column poses a serious safety hazard to anyone working in its vicinity. In worst-case scenarios, structural failure could lead to fatalities.

Under the Work Health and Safety Act 2011, business owners and leaders have a duty to provide a safe workplace “so far as is reasonably practicable.” Ignoring impact protection exposes both the business and its leaders to significant penalties.

What looks like “just a dent” could end up costing thousands or importantly a fatality or serious injury.

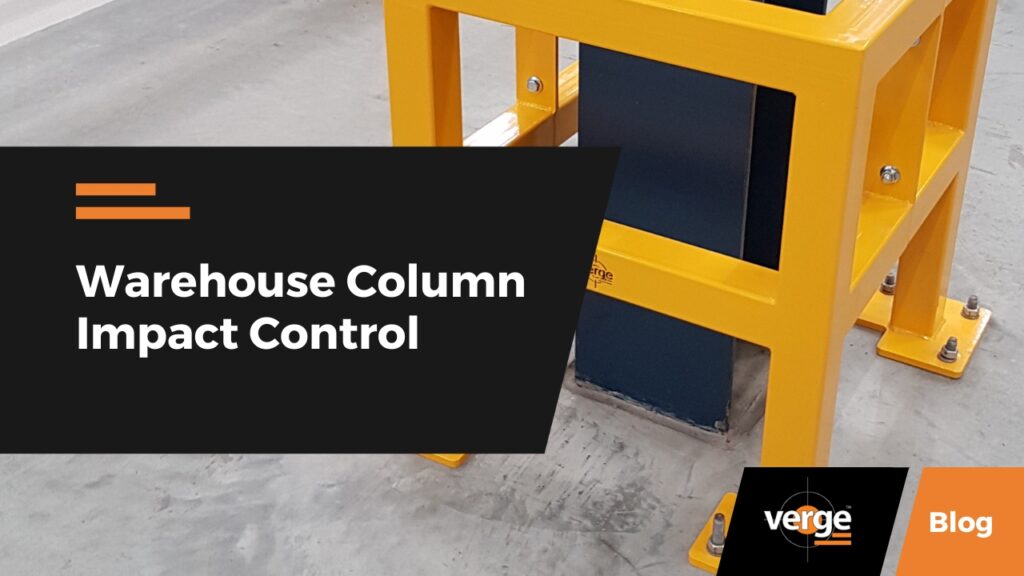

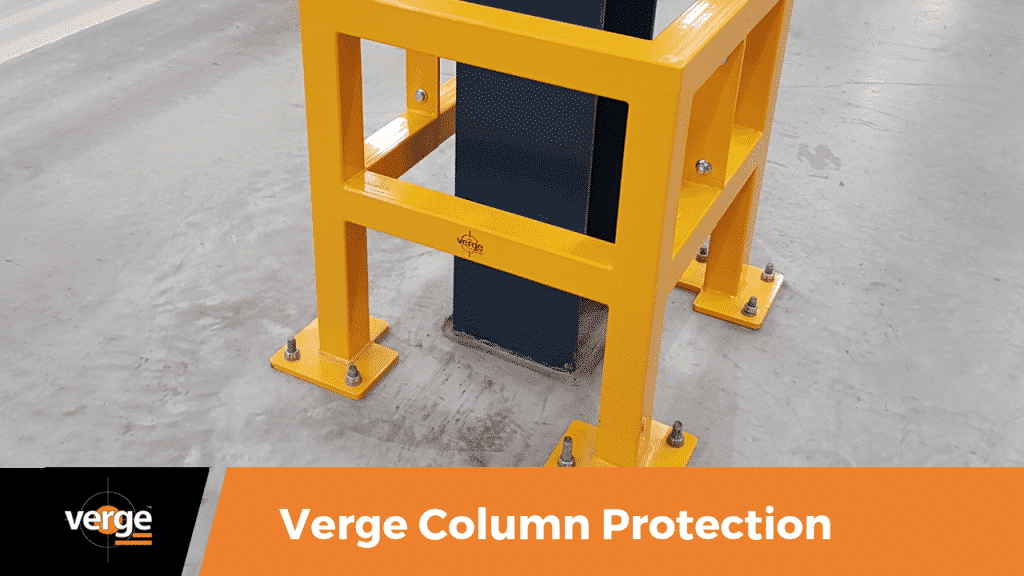

Column protectors are designed to absorb and deflect the force of impacts, shielding structural supports from damage. Made from durable materials like polyethylene or reinforced steel, they create a buffer between moving vehicles and critical infrastructure.

The benefits of column protectors include:

In short: column protectors are not an optional extra. They are an investment in safety, compliance and long-term operational efficiency.

Not all parts of a warehouse carry the same risk. When reviewing your facility, pay special attention to:

If these areas in your warehouse are not currently protected, they should be.

Column protectors play a vital role in helping businesses meet compliance obligations under WHS legislation. SafeWork NSW and other regulatory bodies emphasise the importance of eliminating risks where possible and minimising them through effective controls when elimination is not practical.

Impact protection falls squarely into this category. By installing column protectors, PCBUs (Persons Conducting a Business or Undertaking) can demonstrate that they have taken “reasonably practicable” steps to manage foreseeable risks, a key test in WHS compliance.

If your warehouse has not yet addressed column protection, here’s where to start:

Column protectors are a critical control, but they work best when combined with broader traffic management strategies. These may include:

Together, these measures create a safer warehouse environment where risks are controlled at multiple levels.

Too often, businesses only take column protection seriously after an incident has already occurred. But by then, the damage, financial, operational or human may be too late to undo.

Column protectors are a relatively small investment that can prevent catastrophic outcomes. For warehouses and storage facilities, where high-risk interactions between people, vehicles, and infrastructure are part of everyday operations, they are not optional they are essential.

We offer complete safety solutions wherever barriers are required for your industry or workplace. View our product range, or contact the team for more information.

*Applies to online orders only. *Cannot be used in conjunction with any other offer **Must purchase within 3 months of receiving the voucher ***Minimum order $1000

"*" indicates required fields

If you need assistance with selecting a product, would like a quote or want to ask a question please call our friendly team on 1800 765 539